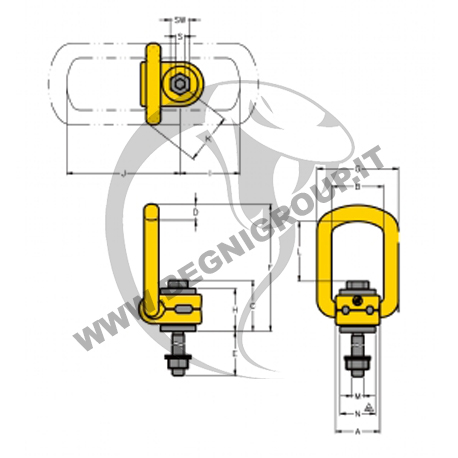

8-231 – SWIVEL LIFTING POINT WITH BRACKET

29 August 2022

8-211 – LIFTING POINT WITH BRACKET

29 August 2022Long stem swivel lifting point with bracket, intended for lifting loads; to be installed on the load itself through a threaded hole.

■ Made of high-strength grade 100 steel alloy.

■ 360° orientable with 90° folding bracket.

■ Wide range of capacities available (M8-M48, 0.3-20 tons).

■ Insertion of RFID microchip for digital management of the product (traceability, inspections, maintenance).

■ Compliant with DM2006/42/CE and EN1677-1.

YOKE® is a leading manufacturer of top-quality swivel lifting points made of grade 100 steel.

Begni Group is the distributor for southern Europe.

■ Identical load capacity in all load directions.

■ All load bearing elements are 100% Magnaflux verified.

■ Traceability of individual forged parts and screw.

■ All Yoke lifting points meet or exceed all ASME B30.26 requirements.

■ Quick and easy assembly, only one threaded hole is required.

■ Metric thread, sizes: M8 – M48.

■ Load capacities (90°): 0.3 t – 20 t.

■ Identical load capacity in all load directions.

■ 360° rotatable with 90° folding bracket.

■ Made of high-strength grade 100 steel alloy: precision forged and heat treated for high performance.

■ Epoxy resin coating, effectively preventing surface corrosion.

■ Clear engraving of the manufacturer’s name, load capacity (WLL), CE mark, thread on the body of the eyebolt.

■ Safety factor 4:1.

■ Tested in accordance with EN1677-1.

■ Individual forged parts and screws are traceable to the test certification.

■ Bolts are metric thread.

■ Load bearing parts are 100% Magnaflux tested after heat treatment.

■ Tested to 2.5 times WLL.

■ Tested to 20,000 fatigue cycles.

Different thread types and shank lengths available on request. The device is not suitable for rotation under load.

Caution: Do not exceed the working load rating (WLL).