WIRE ROPE SLINGS, EYE-EYE

23 September 2022

EDGE PROTECTORS

26 September 2022Begni Group assembles grommets in galvanized steel wire rope with textile core.

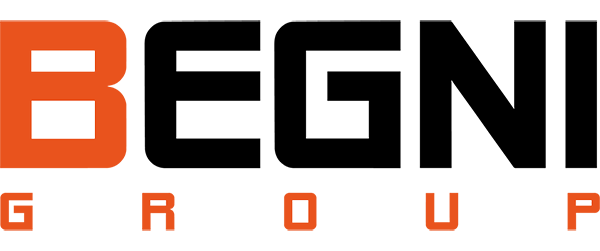

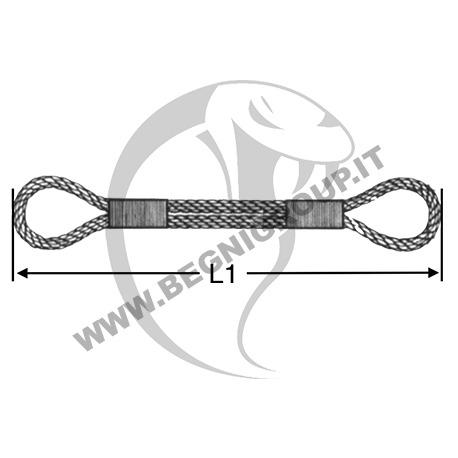

When requesting, the length L must be specified (useful working length, measured between the load-bearing points of the sling, in the absence of load).

The slings are supplied with an identification plate and a CE Declaration of conformity, in accordance with the Machinery Directive 2006/42/CE. On request, they can be equipped with a SupraTag digital chip.

■ Grommets made by qualified operators.

■ Produced in compliance with EN13414-2.3 and DM2006/42/CE.

■ Load capacity plate with serial numbering.

■ Safety factor 5:1.

■ Working and storage temperatures -20° +100°C.

They can be:

■ continuous loop;

■ continuous loop with bindings.

Tech for Safety

Possibility to apply the NFC-RFID microchip (Tech for Safety). Microchip for digital management of the product (documentation at hand, traceability, pre-use control, quarterly inspections).

Proof Test

Possibility to test the load of the slings on our internal Test Bench and, upon request, a customer representative and a third party representative can be present.

Tech for Safety: it is possible to apply an NFC-RFID microchip to the sling.

■ Manufactured in compliance with EN13414-2,3 and DM2006/42/CE.

■ Load capacity plate with serial numbering.

■ Safety factor 5:1.

■ Steel wire rope grommets with textile core made by qualified operators.

■ WLL: from 1.9 to 25.3 t.

■ Manufactured in compliance with EN13414-2.3 and DM2006/42/CE.

■ Capacity plate with serial numbering.

■ Safety coefficient 5:1.

■ Working and storage temperatures -20° +100°C.

For more information do not hesitate to contact us: our sales technicians will indicate the most suitable products for your applications.