HIGH-RESISTANCE STEEL OMEGA SHACKLE WITH YOKE BRAND

12 July 2024

SWIVELING POINT

12 July 2024Begni Group offers a wide and complete range of lifting shackles, compliant with the EN13889 standard.

■ High resistance alloy steel (body: C40, pin: 40Cr).

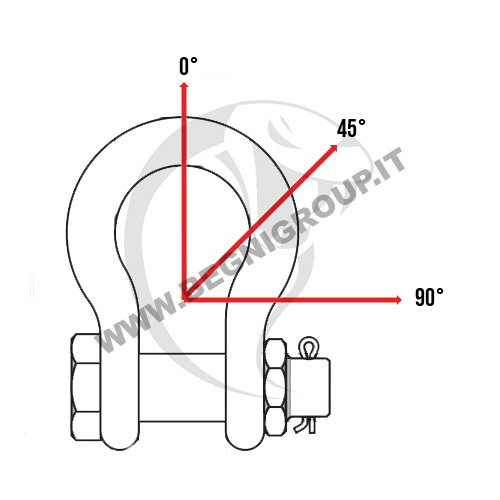

■ Capacity: from 0.3 to 55 t (use in vertical pull 0°).

■ Hot dip galvanizing.

■ Safety factor 6:1.

■ 100% Magnaflux tested.

■ Tested at 20,000 fatigue cycles at 1.5 times the WLL.

■ Each component is marked with the batch number that links it to the test certificate with complete traceability of the raw material used.

■ Possibility of applying the NFC-RFID microchip (Tech for Safety). Microchip for digital management of the product (documentation at hand, traceability, pre-use control, quarterly inspections).

■ 100% Magnaflux tested.

■ Tested at 20,000 fatigue cycles at 1.5 times the WLL.

■ Each component is marked with the batch number that links it to the test certificate with complete traceability of the raw material used.

■ Possibility of applying the NFC-RFID microchip (Tech for Safety). Microchip for digital management of the product (documentation at hand, traceability, pre-use control, quarterly inspections).

■ High resistance alloy steel (body: C40, pin: 40Cr).

■ Capacity: from 0.3 to 55 t (use in vertical pull 0°).

■ Hot dip galvanizing.

■ Safety factor 6:1.

■ 100% Magnaflux tested.

■ Tested at 20,000 fatigue cycles at 1.5 times the WLL.

■ Each component is marked with the batch number that links it to the test certificate with complete traceability of the raw material used.

■ Possibility of applying the NFC-RFID microchip (Tech for Safety). Microchip for digital management of the product (documentation at hand, traceability, pre-use control, quarterly inspections).

For more information do not hesitate to contact us: our sales technicians will indicate the most suitable products for your applications.