“High performance” round slings are defined as such because they are made with a special high modulus polyethylene fiber, which combines high tenacity and very low elongation.

Properties of HMPE / UHMWPE fiber

High performance polyethylene fibre is identified by the acronyms HMPE

(High Modulus Polyetylene) or equally UHMWPE (Ultra High Molecular Weight Polyethylene).

■ Tenacity 15 times higher than steel.

■ Weight 10 times less than steel.

■ Floats on water (specific weight = 0.97 g/cm3). Does not absorb humidity.

■ It does not suffer from fatigue stress (bending and torsion).

■ Excellent resistance to chemical agents and UV rays.

■ Melting temperature 140°C.

Characteristics of HMPE round slings

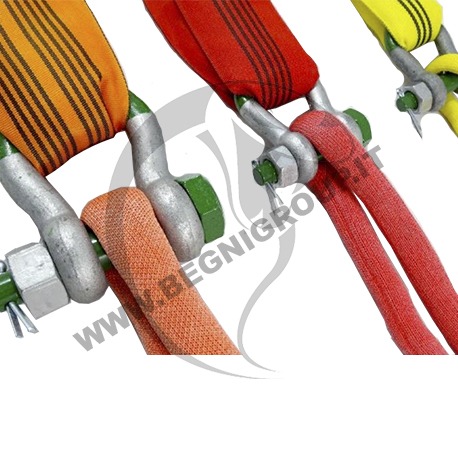

HMPE round slings consist of two parts: the load-bearing core and the core cover. The core is always made of HMPE. Different cover materials can be chosen, depending on the use of the sling.

■ Robust and flexible textile structure: adapts perfectly to the shape of the load.

■ Working load (WLL) up to 600 t.

■ Safety factor 7:1.

■ Breaking load (MBL) 4200 t.

■ Minimum elongation (0.5% of WLL; 3% of breaking load).

■ Lengths: 0.5 – 35 m.

■ High resistance to abrasion.

■ Working and storage temperatures: -40° +70°C.

Turnkey solutions

Begni Group provides turnkey solutions by developing projects based on specific customer needs.

Contact us!

Our sales engineers will advise you on the most suitable products for your applications.

_____________________

Dyneema® is a registered trademark of DSM BV.

Showing all 4 results