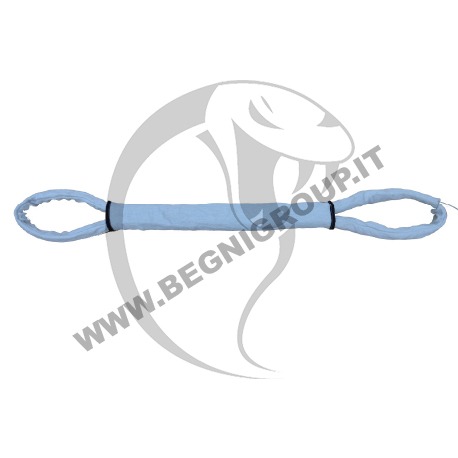

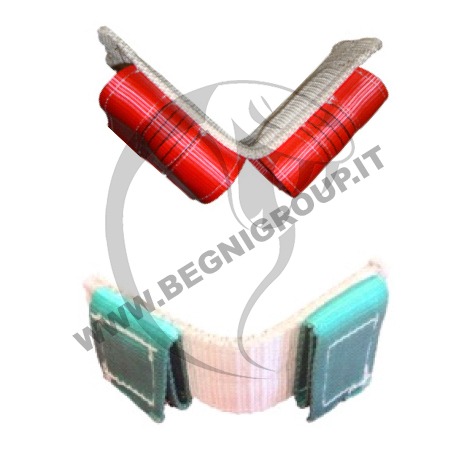

TUBULAR PROTECTIONS IN DYNEEMA® AGAINST THE RISK OF SLING CUTTING

30 August 2022

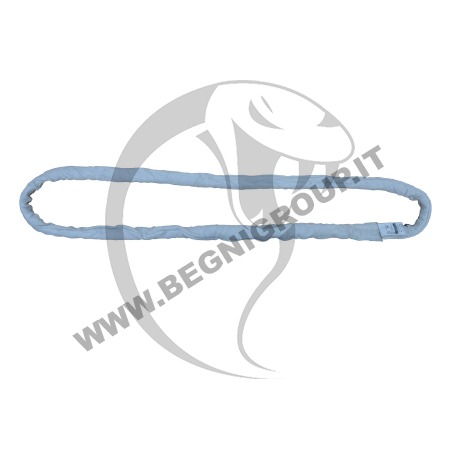

WIRE ROPE ENDLESS SLINGS

30 August 2022“High performance” round slings are defined as such because they are made with a special polyethylene fiber (HMPE) precisely defined as “high performance” due to its formidable properties.

Both the load-bearing part (core) and the outer sleeve (cover) are made of HMPE fiber, to ensure excellent resistance against wear and abrasion.

- High tenacity (15 times higher than quality steel).

- Low elongation (0,5% at WLL).

- Low weight (10 times lower than steel).

- Superior quality material.

- Compliant with EN1492-1.

- Possibility of applying NFC-RFID microchips (Tech for Safety).

- 100% HMPE fiber both in the core and in the cover sleeve.

- Ultra-compact sleeve, resistant to wear and abrasion.

- WLL up to 350 ton.

- Min elongation at WLL (0,5%).

- Safety Factor 7:1.

- Min Length = 1 m.

- MAX Length = 50 m.

- Working temperature: -40°C +70°C.

- Floats on water (specific weight = 0.97 g / cm3). • Excellent resistance to chemical agents.

- Excellent resistance to chemicals.

- Excellent resistance to chemical agents.

- Excellent resistance to UV rays.

- Compliant with: DM2006/42/CE, EN1492-2.

Before using the products, carefully read the safety instructions.

For further information, please contact us: our sales technicians will indicate you the most suitable products for your applications.

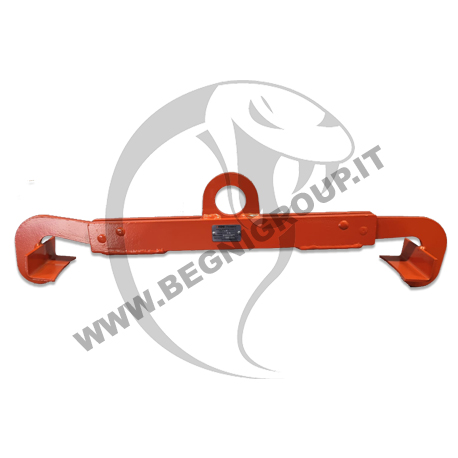

According to EN-1492-1:2000+A1:2008 (C.3.6 e D.3.7), slings should be protected from edges, friction and abrasion, whether from the load or the lifting appliance (shackles, hooks, lifting points). Where protection against damage from edge and / or abrasion s supplied as a part of the sling, this should be correctly positioned.

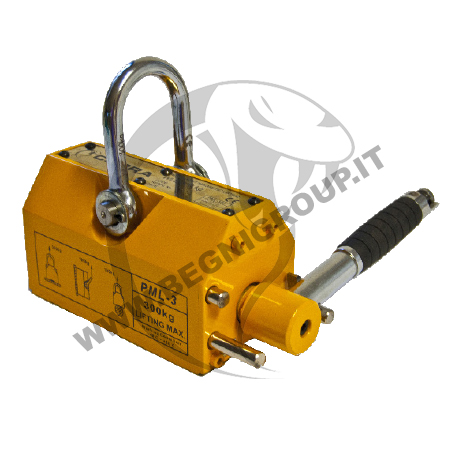

BEGNI Group supplies the most adequate protections to safely manage even the most critical lifting operations.