SUCTION CUPS FOR SHEET METAL

24 February 2025

LASHINGS NETS

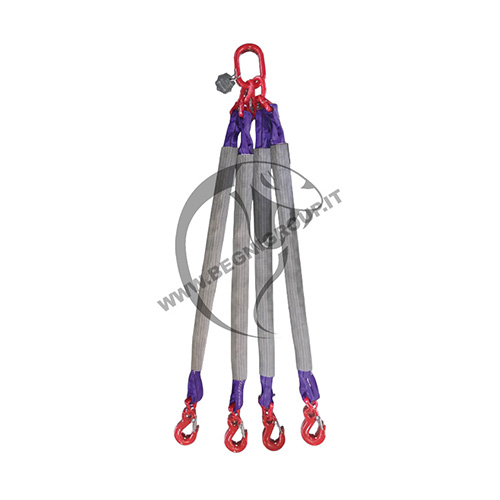

25 February 2025The Begni Group 2WHD and 4WHD slings are made up of two parts:

■ The 2W or 4W load-bearing sling made with 2 or 4 layers of high tenacity polyester tape.

■ The special HDT sleeve made of cut-resistant Dyneema® fiber.

The HDT sleelve is fixed to the sling using a strap that passes around the eyelets. In this way, the sleeve is always taut along the sling, protecting it from the risk of cutting along its entire length, avoiding it from curling up and leaving some parts exposed.

They are designed for lifting loads in basket mode where the risk of cutting is high (metals, stone, concrete, glass, heavy carpentry).

■ Compliant with EN1492-1.

Dyneema® is a registered trademark of Royal DSM N.V.

■ Robust and flexible textile structure: adapts perfectly to the shape of the load.

■ Maximum protection against sharp edges.

■ Excellent tear resistance when subjected to high pressure.

■ Very high load capacity (15 times higher than steel).

■ Minimum elongation (0.5% of WLL).

■ Very low weight (10 times lower than steel).

■ Superior quality materials.

■ Possibility of applying NFC-RFID microchips (Tech for Safety).

■ Possibility to repair damaged slings by replacing only the HDT sleeve.

■ It does not absorb humidity.

■ Long life cycle.

■ 100% HMPE fiber both in the core and in the cover sleeve.

■ Ultra-compact sleeve, resistant to wear and abrasion.

■ 100% Dyneema® HDT sleeve ultra-cut resistant.

■ WLL up to 10 t.

■ Min elongation at WLL (0,5%).

■ Safety Factor 7:1.

■ Min Length = 1 m.

■ MAX Length = 20 m.

■ Working temperature: -40°C +70°C.

■ Floats on water (specific weight = 0.97 g / cm3).

■ Load capacity plate with serial numbering.

■ Excellent resistance to chemical agents.

■ Excellent resistance to UV rays.

■ Compliant with: DM2006/42/CE, EN1492-2.

Before using the products, carefully read the instructions for safe use.

For further information, please contact us: our sales technicians will indicate the most suitable products for your applications.

According to EN-1492-1:2000+A1:2008 (C.3.6 e D.3.7), slings should be protected from edges, friction and abrasion, whether from the load or the lifting appliance (shackles, hooks, lifting points). Where protection against damage from edge and / or abrasion s supplied as a part of the sling, this should be correctly positioned.

WARNING

Damaged or bad used protections compromise the safety in lifting operations.

■ Inspect before use for cuts and tears.

■ Prevent protection and sling from slipping or sliding across load edge.

For further information, please contact us: our sales technicians will indicate you the most suitable products for your applications.