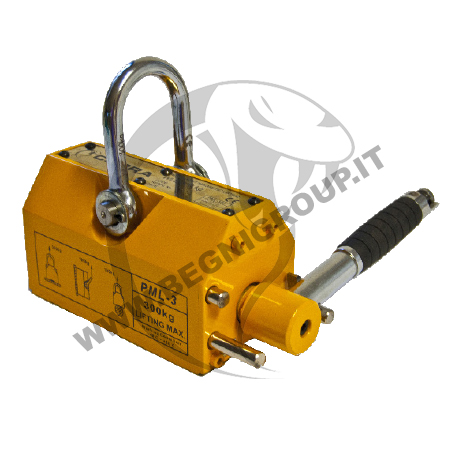

BEGNI GROUP COBRA® tough quality lifting clamps guarantee a high performance and a long operational life. They have “heavy duty” welded shell bodies, made of high high-quality carbon steel. The cam is made of alloy steel, high frequency hardened for a greater durability. The lightweight and streamlined design make them easier to handle. They meet all Standards and requirements such as: European Standard EN13155 and European Machine Directive 2006/42/CE.

They are available in 2 types:

CDH (Standard)

Clamp designed for vertical lifting and transport of steel plates and structures.

Safety mechanism: clamps do not slip when lifting force is applied and when the load is lowered. The clamp is locked in both the closed and open position.

WLL up to 12 ton.

CD (with Shackle)

Clamp designed for vertical lifting, transporting and turning of all steel plates and structures. Articulated lifting shackle guarantees a pressure grip in every position, even with side loading up to 90 degrees.

Safety mechanism: clamps do not slip when lifting force is applied and when the load is lowered. The clamp is locked in both the closed and open position.

WLL up to 16 ton.

- Quality steels: COBRA® vertical lifting clamps CDH and CD are made of top-quality steel and fully comply with European standards in Machine Directive 2006/42/CE.

- Safety mechanism: COBRA® vertical lifting clamps CDH and CD adopt a safety mechanism which consists of a locking device, a tension spring and a lever. Once the lever has been operated, the safety mechanism provides a pre-tensioning of the cam on the steel plate, ensuring that the clamp does not slip when lifting force is applied. When a load is being lifted the clamping force on the cam is increased by the weight of the load. When the load is lowered the safety mechanism ensures that the clamp will not work itself loose.

- Large warehouse stock: the wide availability of products allows very fast delivery times to process even the most urgent orders.

- Tech for Safety: it is possible to apply an NFC-RFID microchip for digital product management (traceability, inspections, maintenance).

- WLL up to 30 ton.

- Min. WLL is 10% of max WLL.

- The surface of the load to be lifted must have a maximum hardness of HrC 37/345 Hb.

- Working temperatures: -40°C +100°C

- Compliant with DM2006/42/CE and EN13155.

Before using the products, carefully read the safety instructions.

For further information, please contact us: our sales technicians will indicate you the most suitable products for your applications.

- Do not lift more than one sheet at a time.

- Never lift plates heavier than the WLL., as indicated on the clamp and on the certificate.

- Minimum WLL is 10% of Max WLL as indicated on the clamp and on the certificate.

- Do not lift plates which are thicker or thinner than the jaw opening, as indicated on the clamp and on the certificate.

- Take care when lifting from a non-vertical position. The working load limit (WLL) may be considerably reduced in these lifting situations.

- The surface of the material must have a hardness level of max. HrC 37/345 Hb.

- When using a number of lifting clamps at the same time, provide lifting slings or chains of a sufficient length to ensure that the angle between the slings or chains never exceeds 60°.

- Do not place the clamp on tapered or conical shaped sections of the plate or structure to be lifted.

- Avoid free falls or hitting objects of the clamp.